Beam me up, Scotty -

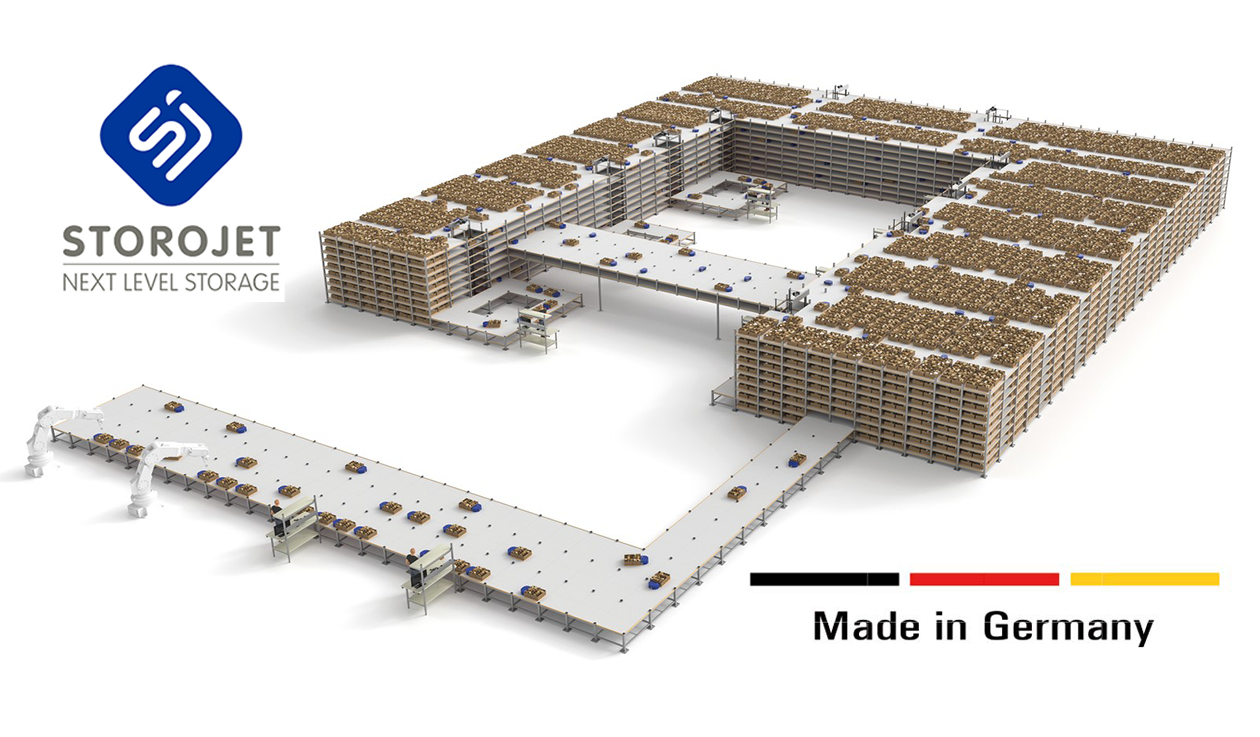

The automatic small-parts storage system: STOROJET

会社概要

Storojet GmbH is an innovative company in the warehouse- and production-automation segment. The company brings together many years of experience with pioneering technology and develops intelligent solutions for the intralogistics of tomorrow. The multiaward-winning STOROJET solution—including the prestigious Rhineland-Palatinate Innovation Award and a place among the top three in the Product of the Year category of the specialist magazine “materialfluss”—has opened a new chapter in intelligent warehouse management.

課題

At the beginning, the idea of developing the STOROJET system arose from the challenges of intralogistics in the company's own divisions. There was a need for a highly redundant automation solution that offers maximum flexibility both in terms of design and the goods to be stored, can be integrated into the processes as easily as possible, and, above all, remains affordable. With new ideas and concepts, the revolutionary STOROJET automation solution with multilayer storage levels and autonomous, driverless transport robots was developed from a test system.

The company opted for the modern Delphi development environment with the Object Pascal programming language for the software development, as they already had extensive know-how and positive experience with this technology.

After an extensive development and testing phase, the automated small-parts warehouse was presented to the public for the first time in 2019.

Applications and Areas of Use

Innovation Stacks Up Here

A notable feature of STOROJET is its modular concept, which can be used not only for the storage automation of small parts or heterogeneous goods but also for production automation.

The extremely flexible, multilevel storage rack offers optimized space utilization in terms of height, surface area, and free geometry. It can be built up to 12 m (39 ft) high and allows customizable spacing of the individual levels between 32 and 100 cm (12.5 and 39 in.)—ideal for a wide range of article heights. The load carriers have a fixed width of 50 cm (20 in.) and a variable length between 50 and 90 cm (20 and 35 in.), with a maximum load of 20 kg (44 lbs.). Their modular design allows a wide range of adaptations, such as subdivided compartments or extra structures for secure storage of even the most complex goods. The shelving consists of classic components and drive-on wooden laminate shelves, can be extended flexibly, and are therefore particularly cost-efficient. Elevators are used to connect the levels, allowing the storage robots to load and retrieve the load carriers.

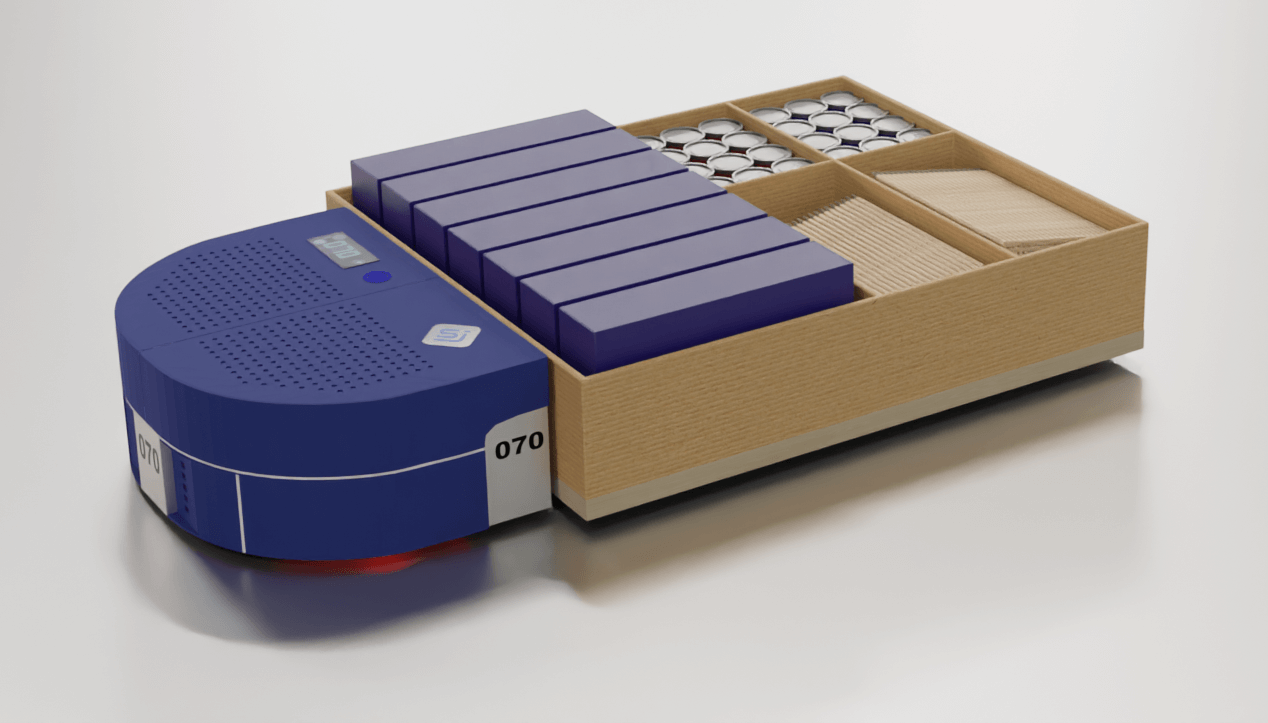

Better than 3D Tetris: The storage robot

The self-developed STOROJET storage robots are roughly the size of a household lawn mowing robot but are much more powerful. The focus was on developing a system that saves as much energy as possible but is still powerful enough to move and position the trailers with the load carriers in the warehouse. The storage robots can move completely independently and are not tied to rails. They navigate autonomously using the suggested routes and the barcodes printed throughout the facility. Due to their high error tolerance, they always find their next location accurately.

All roads lead to Rome: The control software

This masterpiece of software engineering was realized with Delphi and supplemented by a special technological feature. When setting up a racking system for the first time, the floor plan, the levels, the elevators, and the routes must be digitally mapped so that routes can be calculated, similar to a navigation system. The barcodes serve as waypoints for orientation. All robots and elevators communicate via Wi-Fi with the central system, which is written in Delphi. They receive their orders and constantly update supply status and location data. The robots process these autonomously and decide on their own in some cases.

Special attention was paid to redundancy. This means that there are always several elevators that can be used between levels. Several autonomous robots are often available in parallel, as the storage locations are not always freely accessible. If necessary, the mobile load carriers are repositioned in order to reach the required storage trailer.

To ensure that they are always available, even in multiple-shift operation, the software calculates the respective loading status and navigates the robots independently to the loading stations.

Linux on board—and Pascal as a driver

The computers in the robot vehicles are not based on Windows but on a small Linux system, so the developers came up with an ingenious trick for the programming. Avoiding the use of multiple development tools, the development of the robot intelligence was carried out on a parallel project in the Delphi visual development environment. To control the compact computer, a dedicated Object Pascal program code is generated independently of the main system. This is subsequently sent to a Free Pascal compiler, where it is compiled for the Linux platform and distributed directly to the robot systems via Wi-Fi—a solution that is without equal.

State of the art: STOROJET in use

The whole system really capitalizes on its strengths when storing small-product assortments. The robots not only deliver the load carriers to the storage locations but also take goods divided into individual compartments to the workstations when picking orders. As there can be several compartments with different articles per carrier, the exact positions of the articles within it are highlighted for the employees by the pick-by-light system. This technology is used for picking multiple items at once in particular and helps to minimize errors.

The longevity of the Delphi program code and the open standard of the Pascal programming language are crucial for us when developing STOROJET. Delphi is the right choice for us, with a modern IDE and a high level of investment protection over many years.

Dr. Klaus Jeschke, Developer at Storojet GmbH

結論

Through its innovative technology, the STOROJET system has revolutionized warehouse logistics. Storojet GmbH impressively demonstrates how established and modern technologies such as Delphi's can be used efficiently in state-of-the-art automation solutions. The control software of the STOROJET system was developed entirely in Delphi and is the backbone of intelligent warehouse logistics. It not only enables reliable communication among the autonomous robots, elevators, and the central system via Wi-Fi but also enables high-performance route planning and smart order processing.

A notable highlight is the Linux integration for robot intelligence. This approach shows that Delphi, as a modern, durable, and simultaneously innovative programming language, also plays a central role in state-of-the-art Industry 4.0 solutions—flexible, efficient, and ideally suited for sophisticated automation systems.

Visit the storojet.de website for more information and see how customers are enthusiastically using the STOROJET solution.

STOROJET reference: Modellbau Härtle automates 50,000 storage bins

Delphi

Delphi